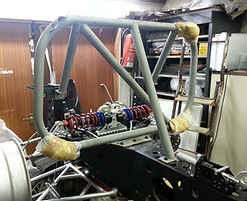

Roll Cage

(a necessary evil)

Sometimes your hand is forced, but it turns out for the best. The roll cage fitted to my car is a case in point.

Originally, I planned to just fit a roll hoop and to that end I bought one and started to make it fit. I didn't want to fit a full roll cage because of my obsession with weight reduction. However, a simple test convinced me that I had to fit one, and not for the obvious reason.

Bob Buck, my suspension guru, thought that my chassis, even though it has been stiffened to Lotus's 26R spec, would be too twisty to cope with over 500BHP. So I did a twisting test. The result wan't as bad as I had feared but not as good as I had hoped.

So, I needed to stiffen the chassis, somehow. First thoughts were to stiffen the body with carbon fibre or build an aluminium cage around the chassis backbone.

In the end, common sense finally reared its ugly head and said, 'Hey, stupid, just fit a full bloody cage. This will do two jobs, something you are always going on about. It will stiffen the chassis and may save your thick head in the event of a crash'.

So a cage it is, despite the weight downside. However, all wasn't lost as I had discovered T45 seemless tube. Superior spec steel that allows thinner walled tube to be used and still be stiffer. Very expensive when compared to CDS, but it will save me around 13-15kg. Also taking into account that the roll hoop I had originally planned to use on its own weighed 14kg, the weight penalty turned out to be only around 19kg. For the additional stiffness (and safety) I can live with that.

So, after many discussions with Martin at MJS Fabrications we agreed on a date to start. This shifted a few times but eventually, in July 2015, I loaded up the trailer with car and T45 tubing (on my own so all the weight saving has already paid off :-) ) and set off for Mundon.

On arrival I started to level up the chassis and this is when I discovered just how out of shape the body is. In the end, after two days of faffing about and head stratching, we decided to work from the chassis and I will see what I can do with the body once I get it home. However, one thing we discovered that I couldn't leave was that the driver's A pillar was 25mm lower than the passenger's. I had to cut through the pillar and tape it up at the right height so that the cage could be built to it.